Controlling pressure differentials in cleanrooms.

09:51 - 19/02/2025 883

Preventing cross-contamination, maintaining cleanliness standards, protecting products and equipment, and optimizing HVAC system performance are all critical roles of pressure differential control.

Innovating airlock technology – off-site fabrication and field assembly to ensure a seamless transition when entering and exiting sterile environments.

Decoding Raised Floors in Cleanrooms for Electronics Manufacturing Plants

The importance of cleanroom lighting

BMS system in a clean room

1. What is pressure difference in a cleanroom?

Pressure difference in a cleanroom is a critical factor in maintaining a clean air environment, helping to control the intrusion of dust, bacteria, and unwanted particles from the outside area. Maintaining proper pressure helps ensure a clean environment, especially in industries such as pharmaceutical manufacturing, electronics, food, and healthcare.

The environment in a cleanroom must be tightly controlled to maintain the appropriate pressure, helping to minimize the risk of contamination from the outside. Pressure differentials can help prevent the movement of air from areas with high levels of contamination to areas with low levels of contamination, thus helping to maintain the required cleanliness standards.

The pressure control system not only helps protect products and equipment but also ensures the safety of people working in the cleanroom. If the pressure difference is not properly controlled, dust, bacteria, and toxic chemicals can enter sensitive areas, affecting product quality and human health.

2. The role of pressure difference control

- Preventing cross-contamination: Pressure difference ensures that clean air always moves from a cleaner area to a dirtier area, preventing cross-contamination of bacteria and dust. This is especially important in pharmaceutical manufacturing and electronic component fabrication, where absolute cleanliness is required.

- Maintaining standard cleanliness: Helps the cleanroom meet strict standards such as ISO 14644-1, GMP, FDA, ensuring the production process meets international standards.

- Protecting products and equipment: If pressure is not controlled, small dust particles or bacteria can enter the production line, causing product damage and reducing equipment lifespan.

- Optimizing HVAC system performance: Pressure control helps the HVAC system operate stably, reducing the load on supply and exhaust fans, thereby saving energy and increasing operating efficiency.

3. Types of pressure in cleanrooms

3.1. Positive Pressure Cleanroom

Positive pressure cleanrooms have a higher internal pressure than the external pressure. When the door is opened, clean air is pushed out, preventing the entry of dust and bacteria.

Applications:

- Pharmaceutical manufacturing

- Medical device manufacturing

- Hospital operating rooms

3.2. Negative Pressure Cleanroom

Negative pressure cleanrooms have a lower internal pressure than the external pressure. This helps prevent the spread of pollutants or bacteria to the outside.

Applications:

- Infectious disease isolation rooms

- Virus research laboratories

- Handling of toxic chemicals

4. Methods of controlling pressure difference

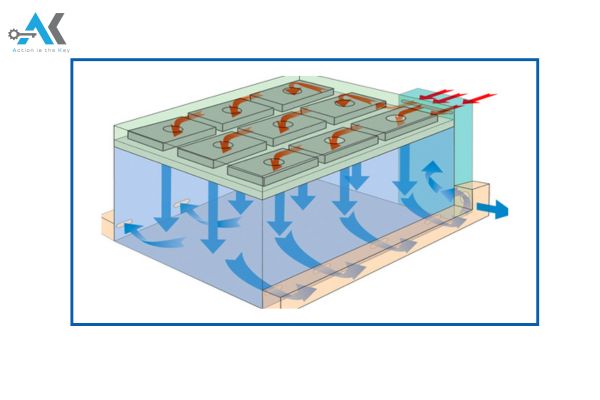

4.1. Fan and air filter system

Using a supply and exhaust fan system combined with HEPA filters helps maintain the desired pressure and ensures clean air. HEPA filters are capable of removing 99.97% of dust particles with a size of 0.3 micrometers, helping to maintain maximum cleanliness.

4.2. Pressure sensors and control system

The pressure sensor system helps monitor cleanroom pressure in real-time, adjusting the supply and exhaust airflow to maintain the desired pressure level. These sensors can be integrated into an automated system to optimize cleanroom operation.

4.3. Door and pressure valve system

Cleanroom doors must be designed to be airtight to prevent air leakage. Pressure regulating valves are used to control airflow, ensuring the pressure difference is always within standard limits.

4.4. Integration of BMS (Building Management System)

Integrating the pressure control system into the BMS helps monitor and efficiently manage the entire cleanroom system. The BMS can automatically adjust supply and exhaust fans based on data from pressure sensors, helping to maintain optimal conditions.

5. Standards for pressure difference in cleanrooms

- ISO 14644-1: Specifies the cleanliness levels of cleanrooms.

- GMP (Good Manufacturing Practices): Cleanroom standards in pharmaceutical manufacturing.

- FDA (Food and Drug Administration): Environmental control requirements in the pharmaceutical and food industries.

- WHO Guidelines: Environmental control guidelines in the production of drugs and biological products.

6. Why is it necessary to tightly control pressure difference?

- Ensuring the safety of products and people: Pressure control helps prevent potential risks such as cross-contamination, viral infection, or the spread of toxic chemicals.

- Compliance with legal regulations: Industries such as pharmaceuticals, food production, and electronics have strict regulations on cleanroom standards.

- Maintaining the durability of equipment and the HVAC system: If pressure is not properly controlled, the HVAC system may have to operate under overload, reducing equipment lifespan.

7. Anh Khang Company's pressure control solutions

Anh Khang Company specializes in providing cleanroom construction solutions, HVAC systems, and professional pressure control. With a team of experienced engineers, we ensure:

- Construction of cleanroom systems that meet international standards.

- Providing optimal pressure control systems, ensuring operational efficiency.

- Consulting, designing, and maintaining cleanroom systems according to customer needs.

If you need advice and installation of a standard-compliant cleanroom system, please contact us immediately for the best support!

For CONSULTATION - DESIGN - CONSTRUCTION of cleanrooms, please contact:

| ANH KHANG CLEANROOM MECHANICAL ELECTRICAL JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Add: Lot B7 - Xuan Phuong Garden - Phuong Canh - Nam Tu Liem - Hanoi. |

12:05 - 28/11/2019 47858

Cleanroom Design and Construction

14:05 - 11/03/2025 22338

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12300

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23454

Electronics Cleanroom Construction

16:15 - 18/03/2021 5967

Warranty Service

16:26 - 28/11/2019 18803

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6207

Technology Production Line Consulting

16:35 - 19/03/2025 19466