BMS system in a clean room

16:40 - 20/03/2025 1103

Discover how the BMS system optimizes clean rooms through environmental control, energy efficiency, and integrated security and lighting, making it ideal for the pharmaceutical and electronics industries

Innovating airlock technology – off-site fabrication and field assembly to ensure a seamless transition when entering and exiting sterile environments.

Decoding Raised Floors in Cleanrooms for Electronics Manufacturing Plants

The importance of cleanroom lighting

Controlling pressure differentials in cleanrooms.

1. What is a BMS System?

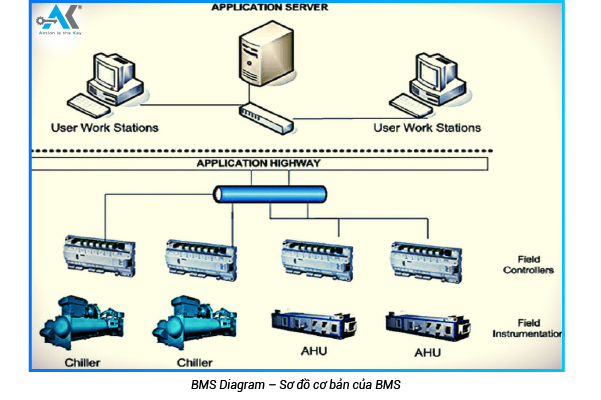

Definition and Role of the BMS System in Building Management

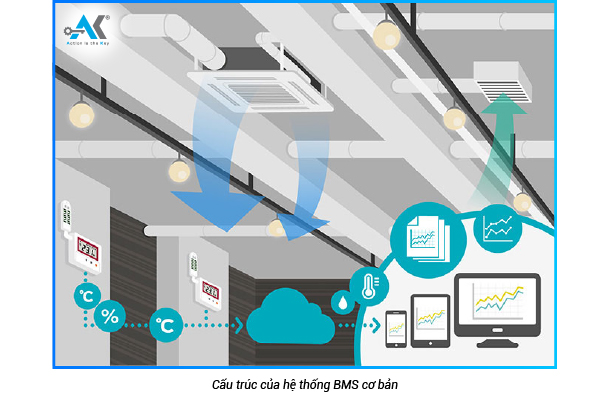

The BMS (Building Management System) is an automation platform that helps control and monitor the building’s infrastructure systems. For clean rooms, the BMS plays a crucial role in maintaining environmental conditions according to strict hygiene standards, helping to protect staff health and optimize operational performance.

2. Why is the BMS System Important in Clean Rooms?

The Benefits of Using BMS in a Clean Room Environment

- Precise environmental control: Monitoring and maintaining temperature, humidity, and air pressure.

- Enhanced operational performance: Minimizes human intervention and optimizes processes.

- Early warning of issues: Sensor systems and notifications help detect problems early.

- Reduced operating costs: Saves energy through automation.

- Improved air quality: Continuous monitoring of air quality to ensure a clean environment.

3. The Main Components of a BMS System

Environmental Control: Temperature, Humidity, and Air Pressure

The BMS system can automatically adjust key parameters to ensure that the clean room environment always meets the required standards.

Air Management: Filtering Dust and Pollutants

This system helps maintain air quality by controlling airflow and using HEPA or ULPA filters.

Monitoring and Alerts: Sensors and Alarm Systems

Sensors are installed to monitor changes in the environment, issuing early warnings when anomalies are detected.

4. BSM Systems in the Pharmaceutical and Electronics Industries

4.1 BMS in the Pharmaceutical Factory

The BSM system helps monitor environmental conditions in drug production, ensuring GMP standards and controlling microbial contamination.

4.2 BMS in the Electronics Industry

Clean rooms in electronic component manufacturing require strict control of temperature, humidity, and static electricity. The BSM system helps reduce the risk of component damage due to unstable environments.

4.3 Investment and Operating Costs of the BSM System

The cost of deploying a BSM system depends on the scale of the clean room and the level of automation. Businesses can choose:

- Basic solution: Only monitors basic environmental parameters.

- Advanced solution: Integrates AI and IoT to automatically analyze and adjust the system.

5. Energy Optimization with the BMS System

How the BMS Helps Save Energy and Reduce Operating Costs

- Smart adjustment of the HVAC system: Reduces energy consumption when not needed.

- Automatic light adjustment: Helps reduce energy waste.

- Integration with renewable energy systems: Utilizes green energy sources to reduce costs.

6. Reporting and Data Analysis in the BMS System

Why Data Analysis is Necessary and How It Helps Improve Performance

The BMS system collects real-time data, providing detailed reports to analyze the performance of equipment, thereby enabling optimization decisions.

7. Integrating the BMS System with Other Systems

The Benefits of Integrating BMS with Security, Lighting, and Equipment Management Systems

- Integration with security systems: Ensures control of access and monitors activities within the clean room.

- Integration with lighting systems: Automatically adjusts lighting to save energy.

- Remote equipment management: Monitors and adjusts the operation of devices through a centralized interface.

8. Conclusion

The BMS system is the optimal solution for managing and maintaining clean room standards. Thanks to its ability to precisely control the environment, optimize energy usage, and provide early warnings of issues, the BMS improves operational performance and ensures a safe working environment for employees. Integrating the BMS with other systems also brings numerous benefits for overall building management.

| ANH KHANG CLEANROOM ELECTRICAL JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Add: Lot B7 - Xuan Phuong Garden - Phuong Canh - Nam Tu Liem - Hanoi. |

12:05 - 28/11/2019 47858

Cleanroom Design and Construction

14:05 - 11/03/2025 22338

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12300

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23454

Electronics Cleanroom Construction

16:15 - 18/03/2021 5967

Warranty Service

16:26 - 28/11/2019 18803

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6207

Technology Production Line Consulting

16:35 - 19/03/2025 19466