Position air return grilles to optimise airflow control in the cleanroom.

09:17 - 21/08/2025 486

Return-air outlet design is the key to maintaining a compliant cleanroom that remains stable and safe over the long term.

Decoding Raised Floors in Cleanrooms for Electronics Manufacturing Plants

The importance of cleanroom lighting

BMS system in a clean room

Controlling pressure differentials in cleanrooms.

Why care about return-air outlets?

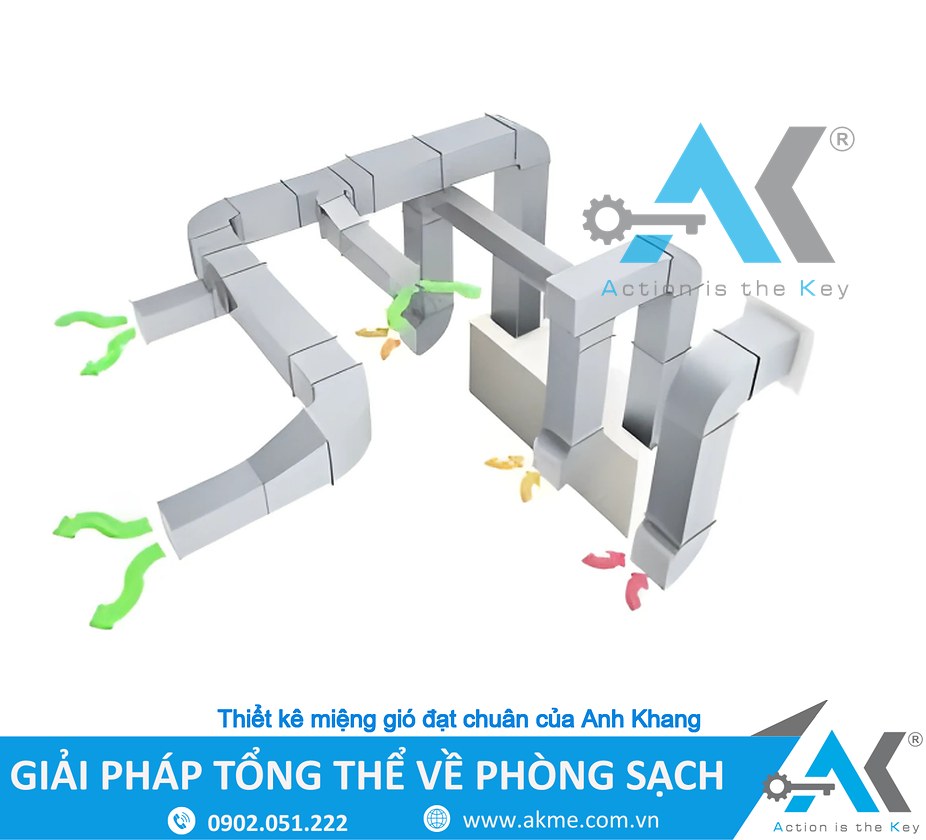

In a cleanroom, air must remain clean and stable to protect products, equipment, and people. The HVAC system is responsible for this, and the return-air outlet is the point where air is collected after circulating through the room.

If return outlets are positioned incorrectly, contaminated air may not be removed in time, leading to particle/microbial build-up and reduced control effectiveness. On the other hand, correct positioning helps a cleanroom operate at peak performance and supports compliance with international standards (ISO, GMP, etc.).

The principle of laminar (unidirectional) airflow

Many cleanrooms apply laminar (unidirectional) airflow—meaning air moves in a single direction, evenly, with minimal turbulence.

- Clean air is typically supplied from the ceiling through HEPA or ULPA filters.

- The airflow then moves downward, carrying particles away from critical zones.

- Finally, air is drawn back through return-air outlets located on the wall or near the floor, to be filtered and recirculated.

If airflow is continuous and unobstructed, cleaning efficiency can be very high.

Avoid “air short-circuiting”

A common design mistake is placing return-air outlets too close to the supply. When this happens:

- Clean supply air is pulled back immediately,

- Before it sweeps through the working zone,

- Resulting in near-zero effective cleaning.

This is known as air short-circuiting, and it must be avoided in cleanroom HVAC design.

-content_1.jpg)

How to position return-air outlets properly

To optimise airflow control, consider the following principles:

- Place return-air outlets at low wall level or below the working height → helps remove contaminated air and heavier particles more effectively.

- Maintain sufficient distance from supply outlets → prevents short-circuiting.

- Calculate return size and quantity → based on cleanroom class (ISO), airflow rate, and occupancy.

- Use smoke testing or CFD simulation → to verify airflow performance before commissioning the cleanroom.

Conclusion

Return-air outlets may look small, but they play a major role in cleanroom performance. A well-designed return-air layout will:

- Ensure clean airflow covers the entire working area,

- Help prevent cross-contamination,

- Support compliance with international cleanroom standards.

In other words, return-air outlet design is the key to maintaining a compliant cleanroom that remains stable and safe over the long term.

| ANH KHANG CLEANROOM M&E JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Add: Lot B7 - Xuan Phuong Garden - Phuong Canh - Nam Tu Liem - Hanoi. |

12:05 - 28/11/2019 47858

Cleanroom Design and Construction

14:05 - 11/03/2025 22335

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12299

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23454

Electronics Cleanroom Construction

16:15 - 18/03/2021 5966

Warranty Service

16:26 - 28/11/2019 18803

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6207

Technology Production Line Consulting

16:35 - 19/03/2025 19465