Comparison of Cleanroom Requirements for Food and Electronics

13:17 - 04/03/2025 4244

Comparison of Cleanroom Standards for Food & Electronics: Bacteria Control vs. Static Electricity Control Ensuring clean, safe production and optimized efficiency. Check it out!

Food Cleanroom Construction: The Decisive Factor for Quality and Safety

Food Cleanroom Construction

☰ Article Table of Contents

Why Compare Cleanrooms for Food and Electronics?

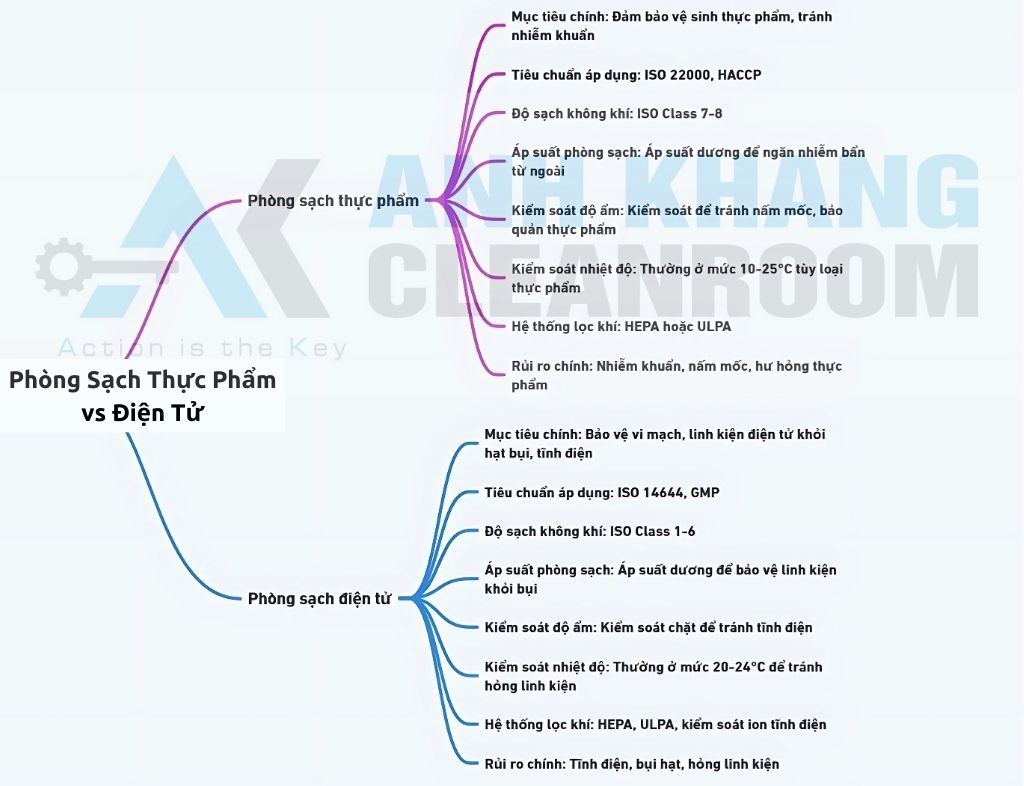

Cleanrooms play a crucial role in many industries, but depending on the specific characteristics of each field, the standards applied can differ significantly. The food industry focuses on controlling microbes and bacteria, while the electronics industry emphasizes static electricity and ultra-fine particles to protect sensitive components.

Real-life example:

- Candy manufacturing plant needs to control bacteria and mold, ensuring products are free from cross-contamination (Cross-contamination Control in Food), avoiding impacts on consumer health.

- Semiconductor manufacturing plant requires an absolutely clean, static-free environment to prevent damage to microchips and semiconductors.

So, what are the similarities and differences between Food Cleanrooms and Electronics Cleanrooms? The detailed comparison table below will help your enterprise understand the standards and operational requirements in each field more clearly.

Commonalities Between Food and Electronics Cleanrooms

Although differing in control objectives, both food cleanrooms and electronics cleanrooms share some common requirements to ensure optimal operating conditions:

✅ Contamination Control: Both industries require strict limitation of contamination sources from air, personnel, and equipment.

✅ Maintaining Cleanroom Pressure: To prevent contaminated air from entering production areas, cleanroom pressure must be precisely controlled according to each standard.

✅ Air Filtration with HEPA/ULPA Filters: Both industries utilize HEPA/ULPA filtration systems to ensure the air cleanliness meets ISO 14644-1 standards.

✅ Temperature and Humidity Control: HVAC systems help maintain stable temperatures as required by each industry, ensuring product quality is not compromised.

Comparison Table of Cleanroom Standards for Food and Electronics

Criteria | Food Cleanrooms | Electronics Cleanrooms |

Main Objective | Control of bacteria, mold, and dust, ensuring food hygiene and safety. | Control of particles and static electricity, protecting electronic components and microchips. |

Applicable Standards | ISO 14644, ANSI/ESD S20.20 | |

Air Cleanliness | Class 100,000 - Class 10,000 | Class 100 - Class 1,000 |

Cleanroom Pressure | Positive pressure to avoid cross-contamination | Negative or balanced pressure, reducing particles and static electricity. |

Humidity Control | 40% - 60% (to prevent mold and maintain product freshness). | 30% - 50% (to reduce the risk of static electricity and protect components). |

Temperature Control | 2°C - 15°C (depending on the type of food) | 18°C - 22°C (to maintain a stable production environment). |

Air Filtration | HEPA, ULPA to remove bacteria and dust | HEPA, ULPA to remove particles smaller than 0.3µm. |

Main Risks | Contamination, mold, affecting food quality and consumer health. | Static build-up, dust, damaging semiconductor components and microchips. |

How to Effectively Apply Cleanrooms in Each Field

For food:

- Maintain strict cleaning procedures to ensure HACCP and FDA standards are met.

- Design positive air pressure flows to protect clean processing areas.

- Strictly control humidity to prevent bacterial growth that could spoil products.

- Refer to our Food Cleanroom Construction process for ensuring safety.

For electronics:

- Strict static control using grounding systems and anti-static floors.

- Cleanroom Design according to ISO 14644-1 standards, ensuring components remain dust-free.

- Optimized HVAC systems, accurately controlling humidity to minimize the risk of microchip damage.

- Ensure that Electronics Cleanroom Construction meets standards, protecting microchips.

Additionally, your enterprise should refer to our Food Industry Cleanroom Design to ensure product quality and safety standards are met.

Optimizing Cleanrooms – A Critical Investment for Every Industry

Whether it is the food or electronics industry, implementing standard-compliant cleanrooms will help enterprises:

✅ Reduce the risk of product damage and optimize production efficiency.

✅ Obtain international certification and expand export markets.

✅ Ensure a safe working environment and enhance brand reputation.

Does your enterprise need consultation on design & Cleanroom Construction for food or electronics?

Please contact ANH KHANG CLEANROOM immediately for the best support!

| ANH KHANG CLEANROOM JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Address: Lot B7 - Xuân Phương Garden - Phương Canh - Nam Từ Liêm - Hà Nội. |

12:05 - 28/11/2019 47755

Cleanroom Design and Construction

14:05 - 11/03/2025 21690

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12231

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23359

Electronics Cleanroom Construction

16:15 - 18/03/2021 5601

Warranty Service

16:26 - 28/11/2019 18461

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6139

Technology Production Line Consulting

16:35 - 19/03/2025 19148