Food Cleanroom Construction: The Decisive Factor for Quality and Safety

11:12 - 04/03/2025 4491

Food cleanroom construction helps control temperature, microbial levels, and humidity to meet HACCP and FDA standards. Discover the optimal solution now!

5 Golden Tips to Reduce the Risk of Cross-Contamination in Food Cleanrooms

Food Cleanroom Construction

Cleanroom Environment – A Direct Factor Affecting Food Quality

In the food processing industry, environmental conditions not only affect product quality but also determine the ability to meet international food safety standards. According to the WHO Air Quality Guidelines , environmental requirements are continuously updated to ensure food safety.

The implementation of HACCP , FDA and ISO 22000 is the basic standard when Constructing Food Cleanrooms to help businesses:

✅ Control the risk of contamination, mold, microorganisms

✅ Meet export standards for food to the EU, US, Japan markets

✅ Enhance product quality, extend shelf life, reduce losses

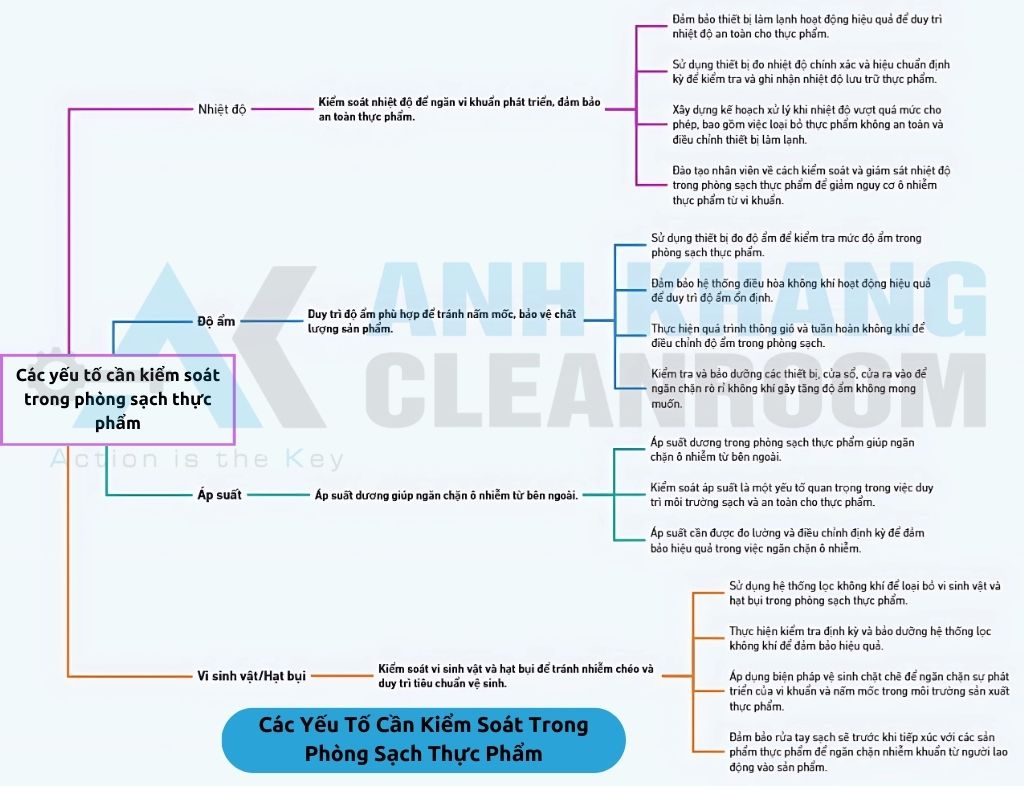

Key Factors to Control in Food Cleanrooms

Temperature Control – Stabilizing Quality & Extending Shelf Life

Improper temperature can lead to:

❌ Faster food spoilage

❌ Rapid bacterial growth

❌ Alteration of product structure, reducing nutritional value

Ideal temperature levels for each food sector:

Type of Food | Optimal Temperature (°C) |

Dairy Processing | 2 - 4 |

Meat and Fish Packaging | -18 |

Confectionery, Chocolate | 18 - 22 |

Beverages | 4 - 8 |

✅ Solution: Apply the HVAC system to maintain a stable temperature and limit fluctuations.

Cleanroom Construction is the solution that helps optimize the temperature control process in cleanrooms.

The standard ISO 14644 provides detailed guidance on the design and operation of cleanrooms.

Humidity Control – Preventing Mold & Microbial Growth

High humidity can cause food to become soft, lose its structure, and spoil quickly , creating favorable conditions for bacteria and mold to thrive.

Ideal humidity levels for each sector:

Food Sector | Optimal Humidity (%) |

Confectionery Factory | 30 - 40 |

Meat Processing | 50 - 60 |

Seafood Packaging | 75 - 85 |

✅ Solution: Use industrial dehumidification systems and HEPA filters to control humidity.

Cleanroom Pressure – Protecting Products from Cross Contamination

In food factories, processing areas need to maintain different pressures to:

✅ Prevent bacteria from unprocessed areas from infiltrating production areas

✅ Avoid cross-contamination between areas

Standard pressure levels for food cleanrooms:

Processing Area | Standard Pressure (Pa) |

Packaging Room | +10 - +15 |

Preparation Room | -5 |

Freezing Room | -10 |

✅ Solution: Use pressure compensation systems to control the pressure differential between areas.

Controlling Cross-Contamination in Food is a key factor in limiting the spread of bacteria.

Cleanroom Quality Monitoring – Ensuring HACCP & FDA Standards

Regular monitoring helps maintain a standardized environment and ensures food safety. The key steps are:

✅ Check temperature, humidity, pressure daily

✅ Evaluate bacteria, microorganisms, dust particles weekly

✅ Calibrate HEPA, ULPA filters, and HVAC monthly

Cleanroom Design plays a key role in maintaining a standardized environment.

Real-world example:

A confectionery factory in Ho Chi Minh City once experienced mold issues on products after dispatch due to unstable humidity. After renovating the cleanroom and installing humidity controllers and temperature sensors, the defective product rate decreased by 80%.

Cleanroom – The Core Solution for Ensuring Food Safety

Constructing food cleanrooms not only helps businesses control microorganisms and maintain product quality but also expands export opportunities.

Food Cleanrooms are the gold standard for every business in the industry.

Do your business need consultation on designing & constructing food cleanrooms that meet HACCP, FDA standards ? Please contact ANH KHANG CLEANROOM for specialized support.

Food Industry Cleanroom Design helps your business achieve optimal quality and safety standards.

| ANH KHANG CLEANROOM JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Address: Lot B7 - Xuân Phương Garden - Phương Canh - Nam Từ Liêm - Hà Nội. |

12:05 - 28/11/2019 47755

Cleanroom Design and Construction

14:05 - 11/03/2025 21690

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12231

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23359

Electronics Cleanroom Construction

16:15 - 18/03/2021 5601

Warranty Service

16:26 - 28/11/2019 18461

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6139

Technology Production Line Consulting

16:35 - 19/03/2025 19147