State of the art Cleanroom Equipment in the Pharmaceutical Industry

15:50 - 03/03/2025 2477

State-of-the-art cleanroom equipment such as the Isolator, Pass Box, and Laminar Flow helps optimize pharmaceutical and medical production. Discover the solution here.

Secrets of Pharmaceutical Cleanroom Construction: Ensuring Absolute Sterility

Pharmaceutical Cleanroom Construction

Why does the pharmaceutical industry need specialized cleanroom equipment?

The pharmaceutical & healthcare industry requires a stringent cleanroom environment to ensure production quality, prevent cross-contamination, and meet the CGMP , WHO and ISO 14644 . One of the most important factors in maintaining aseptic conditions, dust, and microbial control is the modern cleanroom equipment system, thereby helping to optimize the Cleanroom Design.

The choosing the right equipment not only helps optimize operations but also supports Cleanroom Construction in order to save long-term investment costs, ensure products meet international healthcare standards, thereby facilitating the process of Pharmaceutical Cleanroom Construction.

At the same time, businesses in the pharmaceutical & healthcare field should consider applying the Medical Cleanroom Construction to meet the strict industry standards.

Essential equipment in pharmaceutical cleanrooms

ANH KHANG proudly provides Pharmaceutical Cleanroom Equipment with modern technology, ensuring optimal efficiency in the production process.

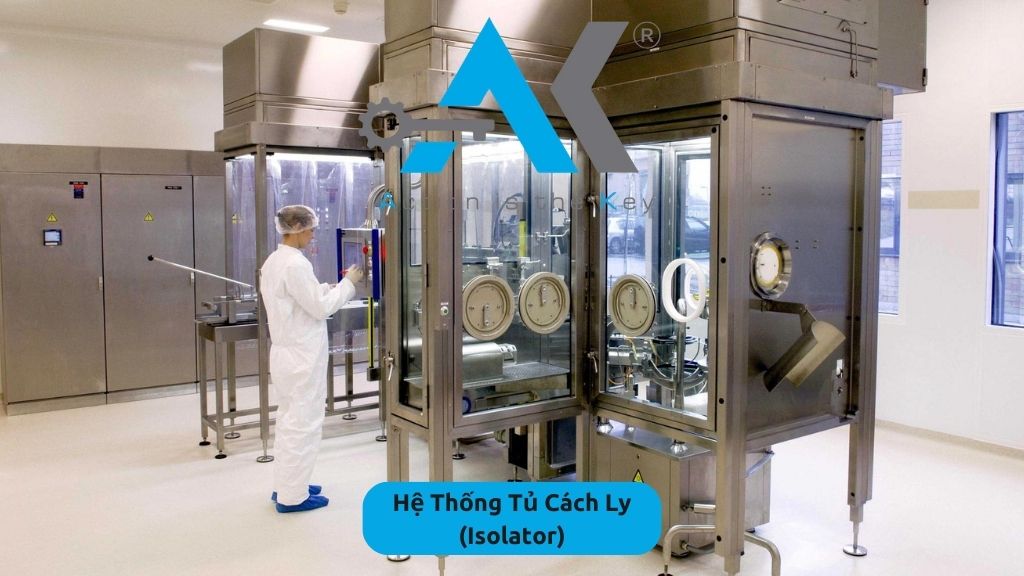

Isolator – Aseptic Isolation System

- Applications: Pharmaceutical compounding, microbiological research, sterile drug storage

- Key Features:

- ✅ Provides a completely sealed environment , eliminating contamination

- ✅ Integrated HEPA filter , ensuring air meets ISO 5 or lower standards

- ✅ Suitable for use in vaccine production, and medical biologics

Pass Box – A Safe Material Transfer Solution

- Applications: Transportation of raw materials and samples between cleanroom areas

- Key Features:

- ✅ Reduces cross-contamination between clean levels

- ✅ Integrated UV sterilization lamp , ensuring samples remain sterile

- ✅ Easy installation & maintenance , reducing operational costs

See more: Cleanroom Equipment and Accessories

Laminar Flow – Unidirectional Airflow for Microbial Control

- Applications: Drug compounding areas, biological research, pharmaceutical sample testing

- Key Features:

- ✅ Provides clean airflow in a specific direction , reducing contamination

- ✅ Maintains cleanliness levels of ISO 5 - ISO 7 , protecting product quality

- ✅ Optimized dynamic design , allowing air circulation without turbulence

Real-world Applications of Cleanroom Equipment in Pharmaceuticals & Healthcare

A pharmaceutical manufacturing plant in Hanoi has applied Pass Box, Laminar Flow, and Isolator to enhance aseptic standards, helping to:

- ✅ Reduce the risk of contamination in drug compounding by 40%

- ✅ Achieve GMP-WHO certification 30% faster compared to conventional plants

- ✅ Increase production efficiency , reducing errors in pharmaceutical testing

Thanks to the scientific integration of cleanroom equipment, the company has optimized operating costs and ensured that product quality consistently meets the highest standards.

In addition, Cleanroom Applications in Food are also being researched and applied in some pioneering industry projects.

Choosing Cleanroom Equipment – Optimizing Investment, Enhancing Efficiency

Cleanroom equipment not only ensures a sterile environment but also directly affects Pharmaceutical Quality , production efficiency, and operating costs.

See more: List of Cleanroom Equipment & Accessories

If your company requires Consultation on Pharmaceutical Cleanroom Construction or need assistance in finding optimal solutions for the pharmaceutical & healthcare industry, please contact ANH KHANG CLEANROOM for specialized support.

| ANH KHANG CLEANROOM ELECTRICAL JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Address: Lot B7 - Xuân Phương Garden - Phương Canh - Nam Từ Liêm - Hanoi. |

12:05 - 28/11/2019 47755

Cleanroom Design and Construction

14:05 - 11/03/2025 21692

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12232

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23360

Electronics Cleanroom Construction

16:15 - 18/03/2021 5602

Warranty Service

16:26 - 28/11/2019 18464

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6140

Technology Production Line Consulting

16:35 - 19/03/2025 19149