Anti-Static Clean Room: Protecting Medical Equipment (Testing Machines, X-Ray)

11:35 - 03/03/2025 6492

Anti-static clean rooms help protect sensitive medical equipment—such as diagnostic machines and X-ray devices—from static electricity damage. Explore comprehensive anti-static solutions.

Medical Cleanroom: The Golden Secret to Maintaining Sterility and Optimizing Operational Efficiency

Comprehensive Hospital Air Quality Testing Solution

GMP or ISO 14644: Which Standard is Optimal for Medical Cleanrooms?

Modern Hospital Cleanroom Design

☰ Article Table of Contents

The Importance of the Electrostatic Protection System in Medical Cleanrooms

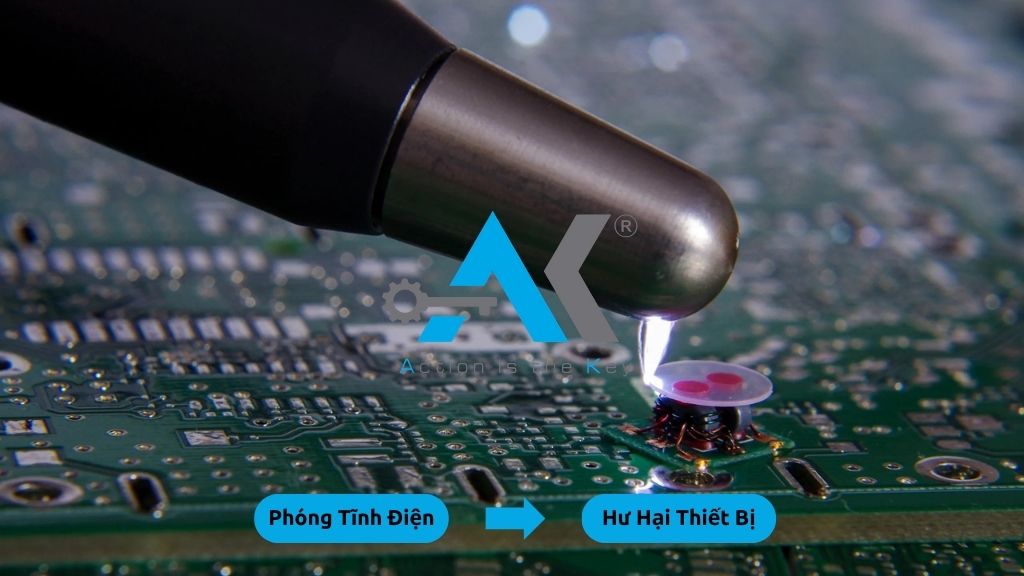

How Does Static Electricity Affect Medical Equipment?

In the medical field, imaging equipment such as X-ray machines, laboratory analyzers, MRI, CT-Scans are highly sensitive to electric fields and static electricity. When charge accumulation exceeds safe limits , they can cause malfunctions, reduce measurement accuracy, and even disrupt the diagnosis and treatment process .

To optimize efficiency and protect equipment, the professional Cleanroom Design is essential.

Additionally, complying with international standards such as ISO 14644 helps ensure that the cleanroom environment meets the requirements.

Medical equipment is often manufactured according to the ISO 13485 standard to ensure quality and safety during operation.

Consequences of Static Electricity in Medical Cleanrooms:

- Electronic component failures in medical equipment , resulting in high repair costs

- Incorrect test and diagnostic results , affecting treatment

- Disruption of medical procedures , impacting patients

Implementing the Anti-Static Cleanroom solution helps enhance equipment protection.

The ESD Mechanism in Medical Cleanrooms

How Does Static Electricity Form in a Cleanroom Environment?

- Friction between material surfaces and humans (floors, chairs, protective clothing...)

- Operation of electronic devices creates charge differences

- Low humidity reduces the ability to dissipate charges, causing static electricity to accumulate longer

✅ Solution: Implement an ESD anti-static system , including conductive materials, grounding, and humidity control, to minimize the risk to medical equipment.

Anti-Static Materials Used in Cleanrooms

Anti-Static Paint for Floors and Walls

- Anti-static epoxy paint , which helps dissipate charges and prevent static buildup

- Vinyl or plastic anti-static flooring , ensuring durability and effective charge dissipation

Static Control Equipment

- Ionizer static eliminator bar , neutralizing charges around medical equipment areas

- ESD anti-static mats , used in areas with laboratory analyzers and X-ray machines

✅ Note: Static electricity can severely impact highly sensitive equipment. Therefore, it is necessary to install the anti-static system according to the standards to ensure the safety of the equipment.

Additionally, complying with the GMP standards for medical cleanrooms will contribute to the stable operation of the system.

The Process of Constructing an Anti-Static Cleanroom

Step 1: Survey & Risk Assessment

- Assess the medical equipment and its sensitivity to static electricity

- Measure surface resistance , and determine the appropriate anti-static material

Step 2: Choosing Anti-Static Materials

- Anti-static epoxy paint for floors and walls

- Anti-static panels , ensuring insulation and effective charge dissipation

Step 3: Installing the Grounding System

- Utilize grounding cable systems to ensure effective charge dissipation

- Check the conductivity to avoid prolonged static buildup

Step 4: Testing, Measurement, and Acceptance

- Measure surface resistance , and evaluate the effectiveness of static dissipation

- Inspect the operation of the ionizer bar , ensuring it does not interfere with medical equipment

This process is carried out according to the professional Cleanroom Construction method.

A Laboratory Section Damaged by Static Electricity

At a large hospital, the laboratory section encountered a serious incident when the biochemistry analyzer was damaged due to accumulated static electricity , causing the hospital to halt operations for 3 days for repairs , which affected hundreds of patients.

After implementing the anti-static cleanroom system , which includes epoxy paint, vinyl anti-static flooring, and a compliant grounding system , the hospital was able to:

- Completely eliminate the risk of equipment damage due to static electricity

- Ensure accurate test results and avoid errors

- Maintain equipment lifespan , saving on maintenance costs

Moreover, implementing the Air Quality Testing Technology will further enhance the efficiency of the system.

In particular, constructing a Hospital Cleanroom is the optimal solution in modern medical environments.

Reputable Contractors for Anti-Static Cleanroom Construction

Static electricity is a major threat in medical cleanrooms, especially for X-ray machines, laboratory analyzers, and imaging devices . Proper construction of anti-static cleanrooms not only helps protect high-value medical equipment , but also ensures absolute accuracy in diagnostics .

This process is carried out according to the Medical Cleanroom Construction standards and is supported by the Medical Cleanroom Consulting Services .

Additionally, complying with the CGMP regulations is a key factor in ensuring safety and efficiency in cleanroom operations.

ANH KHANG CLEANROOM commits to providing a comprehensive anti-static solution , meeting international standards, to help your esteemed enterprises enhance medical service quality & optimize cleanroom operations .

| CÔNG TY CỔ PHẦN CƠ ĐIỆN PHÒNG SẠCH ANH KHANG Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Add: Lô B7 - Xuân Phương Garden - Phương Canh - Nam Từ Liêm - Hà Nội. |

12:05 - 28/11/2019 47858

Cleanroom Design and Construction

14:05 - 11/03/2025 22339

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12301

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23455

Electronics Cleanroom Construction

16:15 - 18/03/2021 5969

Warranty Service

16:26 - 28/11/2019 18803

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6207

Technology Production Line Consulting

16:35 - 19/03/2025 19468