Clean Room Quality Monitoring and Inspection Process

15:19 - 01/03/2025 3735

The clean room quality monitoring & inspection process ensures compliance with GMP and ISO 14644 standards while minimizing construction errors. Explore the detailed stage-by-stage checklist for effective quality control!

Is building a cheap cleanroom truly effective?

Cleanroom Air Control System

Clean Room Installation: Implementation Steps from A to Z

What does the clean room system consist of?

Why is an A-Z Roadmap Needed for Cleanroom Installation?

In the industries of pharmaceuticals, healthcare, food, electronics, cleanrooms are the key element to ensure product quality, safe production processes, and strict compliance with GMP standards, ISO 14644, HACCP. The lack of a clear roadmap in cleanroom design and installation can lead to resource waste, increased costs, and extended timelines. Therefore, the process from surveying, design, installation to acceptance and maintenance must be carried out in a methodical manner, ensuring optimal efficiency.

Furthermore, with the need to optimize costs, choosing affordable cleanrooms is always a solution worth considering.

This article will provide an A-Z roadmap, helping investors, plant managers, and supervisory engineers gain a clear view of the steps to implement a compliant cleanroom, ensuring rapid progress and sustainable efficiency.

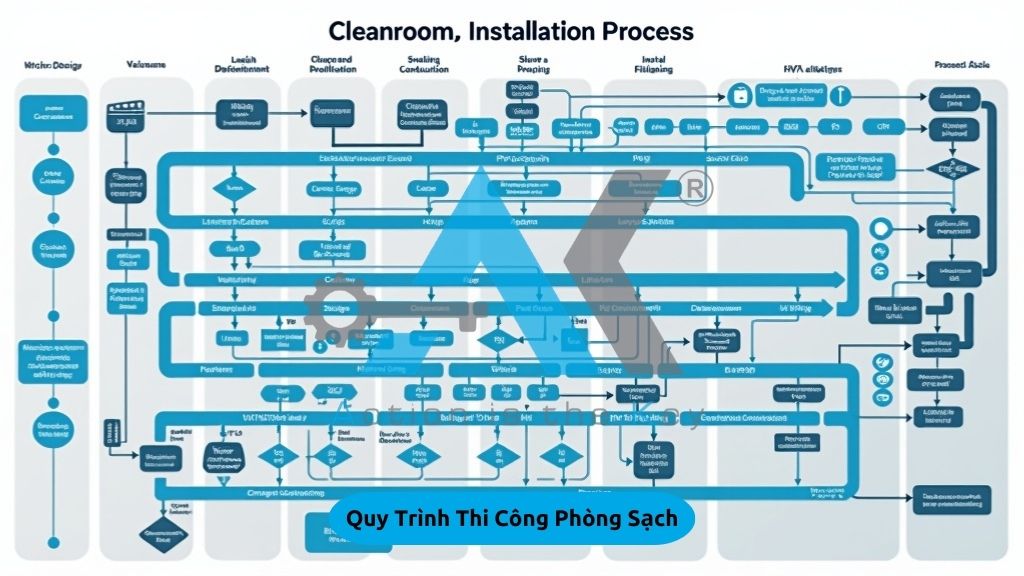

Steps to Implement a Cleanroom

To fully understand the process, your company needs to master the steps for cleanroom construction.

Survey & Needs Analysis

- Identify the type of cleanroom: Pharmaceutical cleanroom, healthcare cleanroom, food, electronics...

- Determine the cleanliness level: ISO 14644 - 1 Class 1 - 9, GMP, FDA

- Survey the environment, contamination sources, specific requirements of the company.

Cleanroom Design

- Draft layout plans for spatial organization, airflow, HVAC system, lighting...

- Calculate pressure differences, airflow direction, heat load, and simultaneously perform cleanroom pressure control.

- Select wall, floor, ceiling materials, and filtration equipment appropriately.

Construction & System Installation

- Construct foundations, install wall panels, ceiling, and floor.

- Install doors, Pass Box, Air Shower, FFU.

- Complete the installation of the electrical system, air conditioning, HVAC.

To ensure the implementation process is professional, your company should also refer to the cleanroom construction process.

It is also important to choose the correct components of the cleanroom system to ensure optimal performance.

Acceptance & Quality Inspection

- Inspect pressure, HEPA filtration, airflow rate, particle count.

- Inspect vibration, noise level, temperature, humidity.

- Perform acceptance testing according to ISO/GMP/FDA standards.

The supervision process must comply with the Cleanroom Quality Inspection standards.

Additionally, acceptance must also meet the cleanroom standards of the industry.

Maintenance and Operation

- Establish a regular maintenance schedule.

- Monitor filtration performance, HVAC system, air quality.

- Upgrade when there are changes in standards or production needs.

Hai Duong Pharmaceutical Plant Project – HD Pharma

One of the exemplary projects applying a methodical cleanroom installation process is the Hai Duong Pharmaceutical Plant – HD Pharma. During the implementation, this company adhered to the roadmap from surveying to acceptance, bringing clear benefits:

✅ Saved 20% of investment costs by choosing appropriate materials and HVAC systems.

✅ Ensured GMP standard – WHO GMP from the first inspection, without wasting time on adjustments.

✅ Shortened the construction timeline by 15%, allowing the plant to quickly start stable production.

View project details: Hai Duong Pharmaceutical Plant – HD Pharma

Contact ANH KHANG CLEANROOM Now

If your company requires detailed consultation on the design, construction, and installation of cleanrooms, ANH KHANG CLEANROOM will be the trusted partner to help your company implement the project in the most efficient, safe, and cost-effective manner.

Learn more: Cleanroom Design and Construction

| ANH KHANG CLEANROOM ELECTRICAL JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Address: Lot B7 - Xuan Phuong Garden - Phuong Canh - Nam Tu Liem - Hanoi. |

12:05 - 28/11/2019 47755

Cleanroom Design and Construction

14:05 - 11/03/2025 21692

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12232

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23360

Electronics Cleanroom Construction

16:15 - 18/03/2021 5602

Warranty Service

16:26 - 28/11/2019 18464

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6140

Technology Production Line Consulting

16:35 - 19/03/2025 19149