Cleanroom Air Control System

08:44 - 03/03/2025 3298

The cleanroom air pressure control system helps prevent cross-contamination and maintains a clean environment that meets ISO and GMP standards. Discover the optimal design and operation now!

Is building a cheap cleanroom truly effective?

Clean Room Installation: Implementation Steps from A to Z

What does the clean room system consist of?

Clean Room Quality Monitoring and Inspection Process

Why is Air Pressure an Important Factor in Clean Rooms?

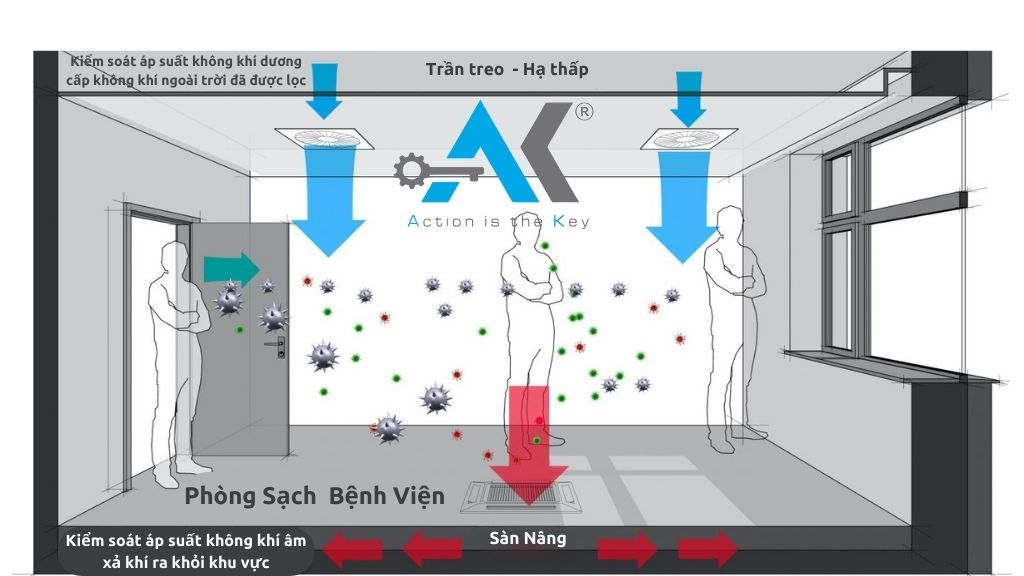

In the production environments of pharmaceuticals, food, healthcare, and electronics, air pressure control is the key factor in maintaining cleanliness levels, preventing cross-contamination, and protecting products. Without stable pressure, dust particles, bacteria, or chemicals can penetrate the production area, seriously affecting product quality.

The clean room air pressure control system is the key solution for every business.

According to clean room standards ISO 14644, GMP-WHO, FDA, clean rooms must adhere to strict regulations regarding pressure differentials between areas to control airflow direction and prevent contaminated air from entering critical areas. Therefore, the air pressure control system is the heart of the clean room, ensuring that the production environment meets the highest safety standards and optimal performance.

Types of Clean Room Pressure and Practical Applications

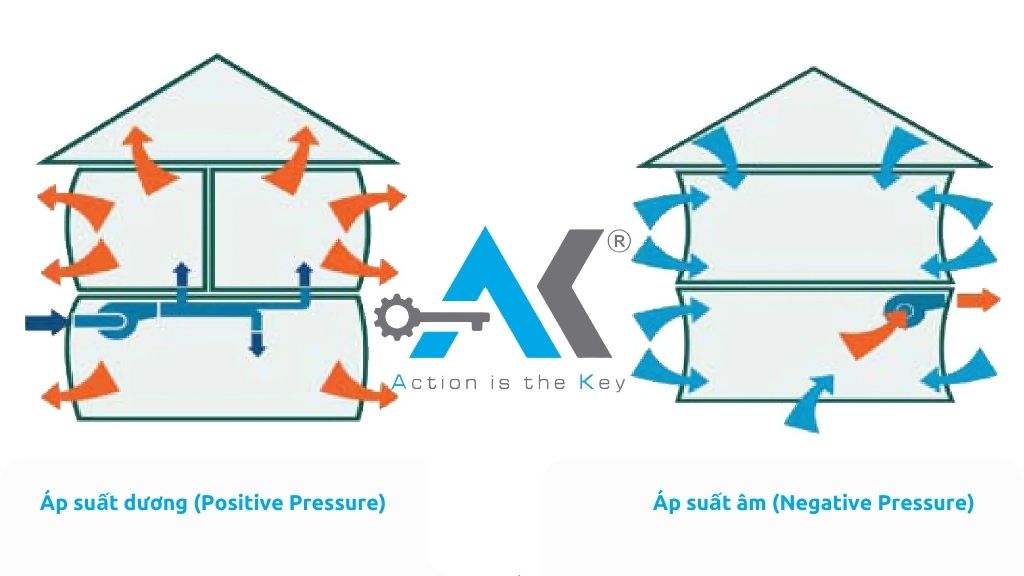

Positive Pressure (Positive Pressure)

- Positive pressure is when the pressure inside the room is higher than the pressure outside.

- Used in pharmaceutical clean rooms, microchip manufacturing, healthcare, where it is essential to ensure that clean air is not contaminated from the outside.

- Positive pressure control systems typically use air balancing doors, HEPA/ULPA filters, and FFU fans to maintain stable pressure levels.

Real-world example:

A pharmaceutical manufacturing plant in Hanoi has invested in a positive pressure control system achieving ISO 14644 Class 1000, which helps reduce the risk of cross-contamination by 80%, ensuring compliance with GMP-WHO standards.

Negative Pressure (Negative Pressure)

- Negative pressure is when the pressure inside the room is lower than the pressure outside.

- Used in medical isolation rooms, microbiology laboratories, and the production of pharmaceuticals containing hazardous chemicals, where it is essential to ensure that air does not leak out.

- Negative pressure control systems use high-capacity exhaust fans, multi-layer air filtration systems, and pressure sensors.

Real-world example:

A central hospital implemented a negative pressure control system in the ward for patients with severe respiratory infections, which helps reduce the risk of bacteria spreading into the external environment.

Clean Room Pressure Measurement and Adjustment Equipment

To maintain stable pressure, clean rooms require an accurate measurement and adjustment system. Below are some important devices:

Differential Pressure Gauge (Differential Pressure Gauge)

- Helps monitor the pressure differences between areas, ensuring the system operates to standard.

- Digital differential pressure gauges provide warnings when pressure exceeds safe thresholds.

Pressure Sensor (Pressure Sensor)

- Pressure sensors help to automatically monitor and adjust via the BMS (Building Management System).

- Data from the sensors can be connected to a central control system, enabling remote monitoring.

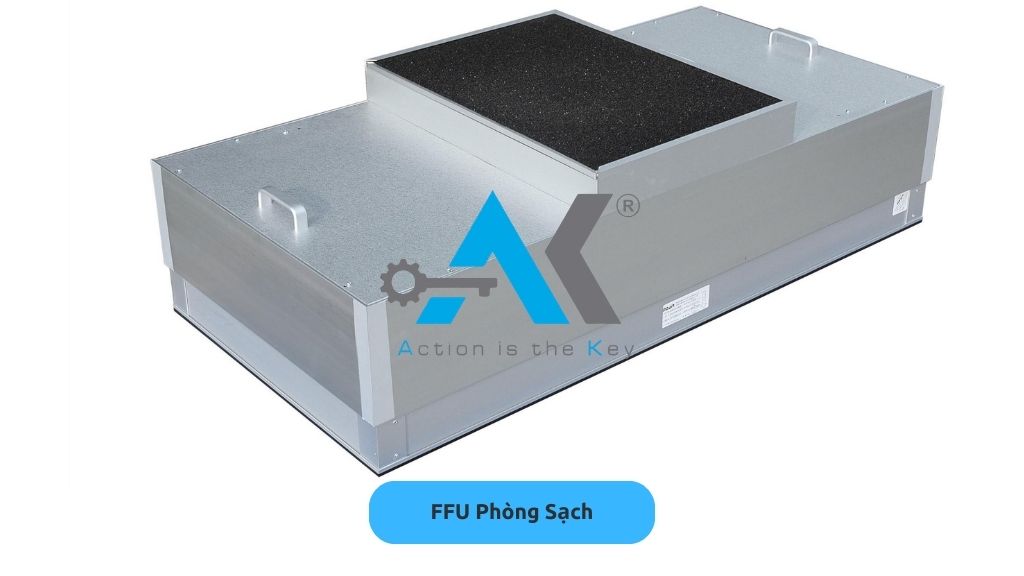

FFU Fans and Airflow Regulation Systems

- FFU (Fan Filter Unit) fans play the role of providing clean air and maintaining stable pressure in the clean room.

- Automatic air balancing doors help to regulate airflow, preventing sudden pressure fluctuations.

To fully grasp the structure, your business can refer to the components of the clean room system.

Steps for Designing and Operating the Air Pressure Control System in Clean Rooms

Implementing a clean room air pressure control system must follow strict procedures to ensure long-term operational efficiency. Below are the key steps in designing and operating the system:

To fully understand the process, your business can refer to the detailed steps of clean room construction.

Step 1: Survey & System Design

- Evaluate the positive/negative pressure requirements for each area.

- Select appropriate insulation materials to minimize pressure leakage.

- Calculate the fan capacity, airflow, and air filtration system.

- At the same time, consultation for Clean Room Design will be proposed according to your business needs.

Step 2: Construction & Installation

- Deploy the system including FFU fans, pressure sensors, and pressure control units.

- Check the connections between rooms and airlock doors to prevent pressure leaks.

- Install the remote monitoring BMS system.

- Clean room construction is carried out according to strict standards.

Step 3: Inspection & Acceptance

- Measure the pressure differential between areas to ensure compliance with ISO/GMP standards.

- Check the air filtration performance, airflow speed, and static pressure.

- Conduct simulated tests for pressure leaks and evaluate remediation capabilities.

Finally, the clean room quality inspection is an indispensable step.

Step 4: Regular Maintenance & Upgrades

- Regularly inspect the differential pressure gauges, fan systems, and sensors.

- Replace the HEPA filters, FFUs, and pressure regulators when due.

- Upgrade the system when there is a requirement to change clean room standards.

Optimal Clean Room Pressure Control Solutions for Businesses

With 15 years of experience in the clean room field, ANH KHANG CLEANROOM provides a comprehensive solution to help businesses design and operate effective pressure control systems:

✅ Design Consultation according to GMP-WHO, ISO 14644 standards

✅ Supply of Pressure Control Equipment: FFU fans, HEPA filters, differential pressure gauges, pressure sensors

✅ Turnkey Clean Room Construction, ensuring compliance with clean room standards

✅ Regular Maintenance & Upgrades, optimizing long-term operational costs

At the same time, your business can opt for the Clean Room Design and Construction solution to optimize operational efficiency and ensure absolute safety.

Additionally, for businesses looking to implement a cost-effective clean room solution while still ensuring quality, we always have a suitable option.

If your business requires detailed consultation on the clean room pressure control system, please contact ANH KHANG CLEANROOM for support.

| ANH KHANG CLEANROOM ELECTROMECHANICAL JOINT STOCK COMPANY Hotline: 1900 636 814 - 0902 051 222 Email: info@akme.com.vn Website: akme.com.vn Address: Lot B7 - Xuan Phuong Garden - Phuong Canh - Nam Tu Liem - Hanoi. |

12:05 - 28/11/2019 47755

Cleanroom Design and Construction

14:05 - 11/03/2025 21692

GMP and ISO Standard Cleanroom Construction

14:18 - 11/03/2025 12232

ISO Standard Medical Cleanroom Construction

14:13 - 28/02/2025 23360

Electronics Cleanroom Construction

16:15 - 18/03/2021 5602

Warranty Service

16:26 - 28/11/2019 18464

Supply and installation of cleanroom equipment

14:50 - 26/11/2019 6140

Technology Production Line Consulting

16:35 - 19/03/2025 19149